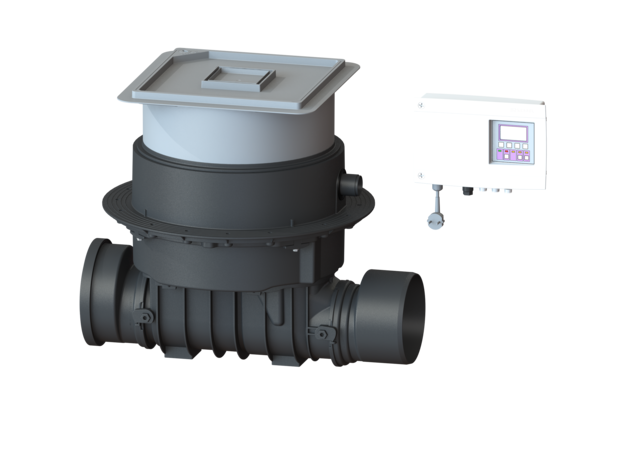

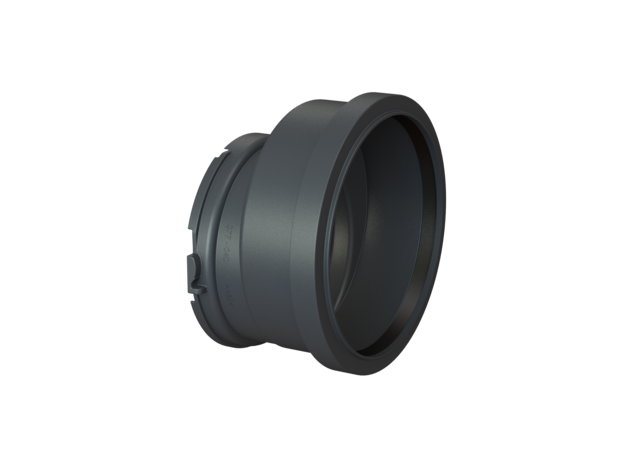

Backwater lifting station Ecolift

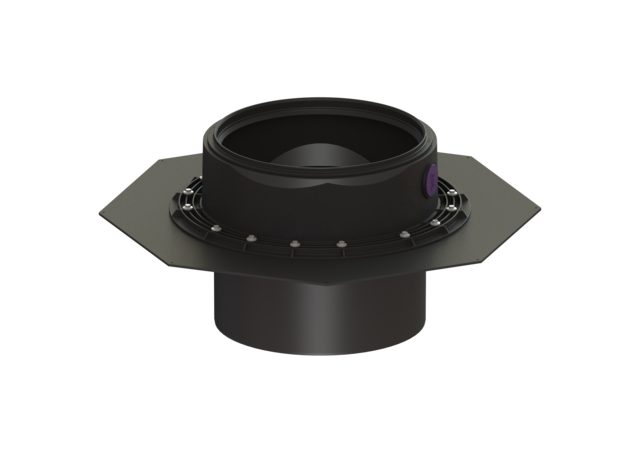

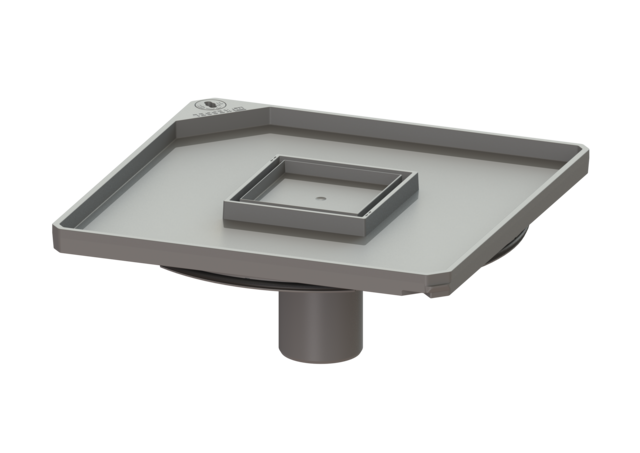

DN 200, Floor slab, tileable

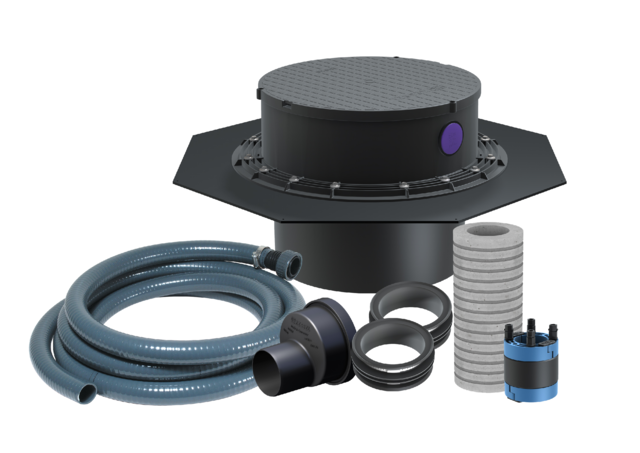

The backwater lifting station for faecal and non-faecal wastewater is equipped with one pump and one motor-driven closure system. The pipe cross-section is normally open and the water drains to the sewer via natural fall. Backwater is detected by an optical probe, which causes the motor-driven closure system to close automatically. During the backwater phase, the water drains via a pressure pipe, which carries the wastewater above the backwater level and into the sewer. Connection hole in the drain body for installation in the ground, incl. seal for pressure pipe and cable conduit. The station is controlled by a user-friendly control unit, which is optionally integrated in the building management system via a potential-free contact, or alarm and collective fault messages can be output via a GSM interface.

- Hybrid function: uses the natural fall to the sewer - pump is only used in case of backwater

- Quiet and energy-saving

- Double safety due to backwater flap and pressure pipe

| Item no. | 21200X |

|---|---|

| GTIN | 4026092046876 |

| Price group | 20 |

Backwater lifting station Ecolift DN 200, Floor slab, tileable

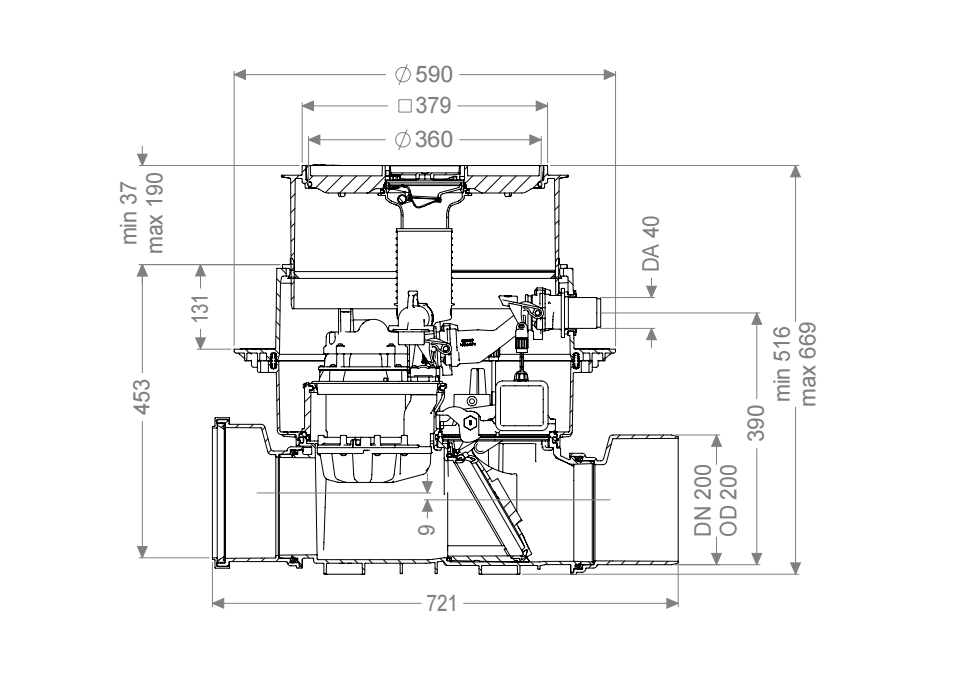

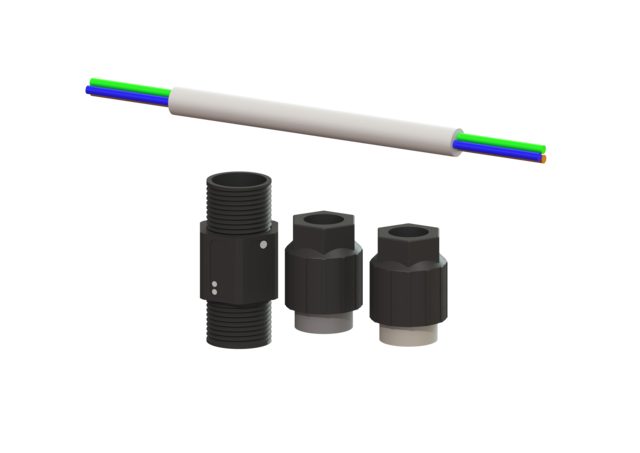

The backwater lifting station for faecal and non-faecal wastewater is equipped with one pump and one motor-driven closure system. The pipe cross-section is normally open and the water drains to the sewer via natural fall. Backwater is detected by an optical probe, which causes the motor-driven closure system to close automatically. During the backwater phase, the water drains via a pressure pipe, which carries the wastewater above the backwater level and into the sewer. Connection hole in the drain body for installation in the ground, incl. seal for pressure pipe and cable conduit. The station is controlled by a user-friendly control unit, which is optionally integrated in the building management system via a potential-free contact, or alarm and collective fault messages can be output via a GSM interface. Type of wastewater: wastewater with sewage Installation situation: floor slab installation Version: Odour trap: Multistop Emergency closure: yes Pump control: Control unit Passage seal for conduit pipe (DN): 50 mm Delivery state: Pre-mounted for final assembly on site (pumps and sensor system must be fitted on site and control unit must be connected) Number of motor-driven backwater flaps: 1 General characteristics: Nominal size (DN): 200 Outer diameter (OD): 200 Note on nominal size: Hydraulics correspond to DN 150 Colour: black Approval: Z-53.2-487 Dimensions: Length: 720 mm Width: 590 mm Cutout dimension, length: 750 mm Cutout dimension, width: 750 mm Tank: Pressure pipe connection (OD): 40 mm Installation depth: 486 - 640 mm Groundwater resistant from lower edge of base section: 3,000 mm Nominal pressure (PN): 6 Drain body: Socket version: including spigot and socket Vertical adjustment: vertically adjustable upper section Coverage features: Type of cover: tileable cover plate Cover material: Polymer Drainage function: yes Max. flooring height: 16 mm Load class: K 3 (EN 1253-1) Length: 366 mm Width: 366 mm Locking: Lock & Lift Pumping device: Pump: SPZ 1000 Number of pumps: 1 Max. pumping capacity: 11.5 m3/h Max. pumping height: 10 m Operating mode: S3 - 50 % Power P1: 1.2 kW Power P2: 0.69 kW Speed: 2,800 U/min Type of fuse required (electrical protection): C 16 A Max. temperature (permanent) of conveyed material: 40 °C Connection type: coded plug Weight: 10 kg Impeller type: Macerator Length of mains cable for pump: 5 m Rated current: 5.2 A Protection class (pump): IP 68 (3m/48h) Protection class: I Type of pump connection cable: H07RN-F 3G 1.0 mm2 Temperature monitoring: integrated Cos phi - power factor: 0.97 Insulation class: F Vertical drop between inlet and outlet: 9 mm Motor type: KSM 140 Protection class motor: IP 68 (3m/48h) Protection class probe: IP 68 (3m/48h) Control: Control unit: Comfort Operating voltage: 230 V Mains frequency: 50 Hz Self-diagnosis system (SDS): yes Battery buffering: yes Multi-line display: yes Log book function: yes USB interface: no GSM interface: no Potential-free contact: yes Standby power: 5 W Protection class control unit: IP 54 Length of mains cable for control unit: 1.4 m Type of level measurement: optical Level measurement instrument: optical probe Alarm sensor: optical probe

Installation Video

| Title | Item no. |

|---|

| Title | Item no. |

|---|

| Title | Item no. | ||

|---|---|---|---|

| Remote signal generator 20 m cable, 2x0.75 q | 20162 | Show |

| Pressure pipe set 5 m pressure hose, DA 40 mm | 28040 | Show |

| Clearance code for potential-free contact | 80077 | Show |

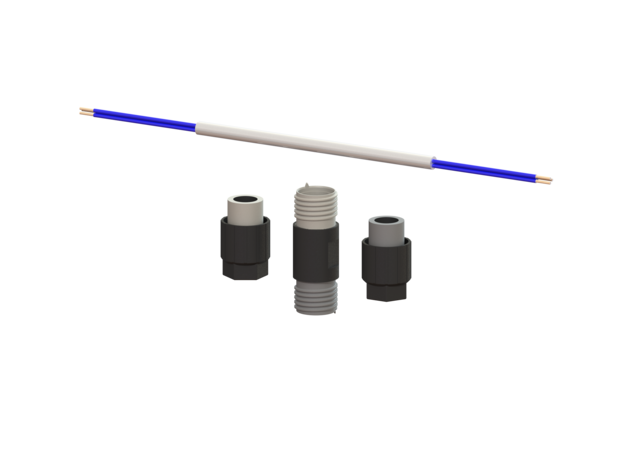

| 10 m probe cable extension set | 80889 | Show |

| Cable extension set for motor 10 m | 80890 | Show |

| Cable prolongation set for pump 10 m | 80891 | Show |

| Extension section H: 200 mm | 83070 | Show |

| Extension section H: 234 mm, with flange and counter-flange | 83073 | Show |

| Extension section H: 360 mm, with central flange | 83075 | Show |

| Waterproof concrete install. kit OD: 40 mm, for building contractors | 83077 | Show |

| Title | Item no. | ||

|---|---|---|---|

| Cover Ecolift outlet side | 21056 | Show |

| Pump cover inlet side | 28054 | Show |

| Vent for Pumpfix Premium | 28060 | Show |

| Active carbon filter | 28061 | Show |

| Pumpfix F Control Unit Komfort - IP 54 | 28071 | Show |

| KTP1000 cutting assembly replacement set | 28075 | Show |

| Replacement pump AqualiftF/Pumpfix F | 28351 | Show |

| One-handed closure for backflow preventer | 680018 | Show |

| Battery 9 V block | 680034 | Show |

| Flap holder for motor-driven and mechanical flap | 680101 | Show |

| Pressure pipe connection Ecolift, installation in floor slab | 680105 | Show |

| Seal for upper section, from 07/2014 | 680150 | Show |

| Drain connection DN 70, with seal | 680215 | Show |

| Seal for cover plate, System 330 mm | 686114 | Show |

| Gasket set (Pumpfix, Ecolift) | 70319 | Show |

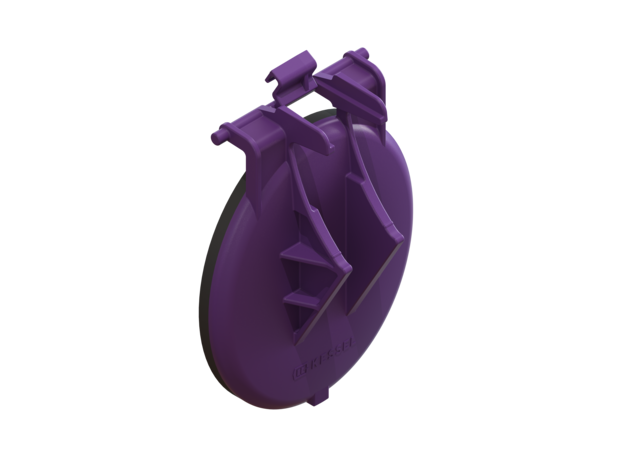

| Motor-driven backwater flap Premium | 80038 | Show |

| Insert part f. motor-driven flap Premium | 80039 | Show |

| Staufix FKA drive motor (KSM 140) 5m | 80076 | Show |

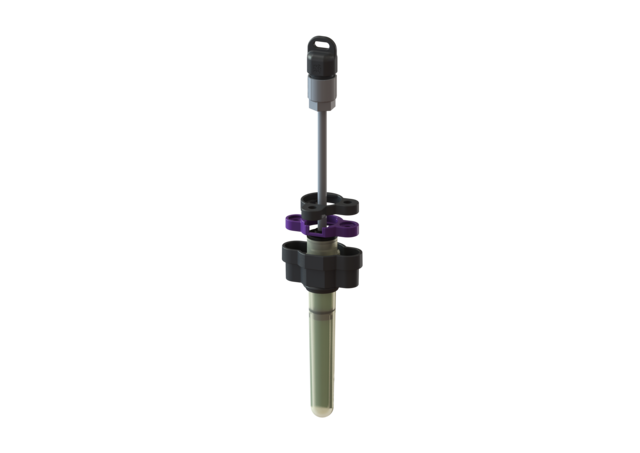

| Replacement set optical probe | 80888 | Show |

| Adapter set optical probe | 80892 | Show |

| Cover plate 366 x 366 mm w. flat drain body, Multistop, tileable | 830045 | Show |

| Upper section System 400 | 830065 | Show |

| Staufix Premium Spigot DN 200 | 83084 | Show |

| Staufix Premium Socket DN 200 | 83088 | Show |

| Manuals | |

|---|---|

| CAD Data | |

| Approval | |

| Declaration of Performance |

- Groundwater resistant from lower edge of base section (ATTR-B12): 3,000 MMT

- Installation situation (ATTR-1):

floor slab installation

- TÜV test mark (ATTR-376):

ID 1111241795

- Country of origin (ATTR-322): DE

- Area of application (ATTR-264): drainage

- Pump type (ATTR-265): Freestanding pump

- Pump shaft position (ATTR-266): vertical

- Pump design (ATTR-267): Dry rotor pump

- Pump hydraulics (ATTR-268): single stage

- Pump suction characteristic (ATTR-269): non-self-priming

- Pump drive (ATTR-270): E-motor for alternating current

- E-motor, type of startup (ATTR-271): direct

- Pump casing material (ATTR-272): Polymer

- Upper tolerance of the nominal frequency (+) (ATTR-275): 3 PROZ

- Lower tolerance of the nominal frequency (-) (ATTR-276): 2 PROZ

- Pump electrical connection (ATTR-277): 1/N/PE 230V

- Motor pump shaft (ATTR-279): continuous

- Shaft seal (ATTR-280): RSSR

- Minimum pumped media temperature (ATTR-282): 0 CEL

- Maximum operating pressure (Pmax) (ATTR-283): 1,000 HPA

- Minimum speed for speed adjustment (ATTR-284): no speed adjustment

- Start-up current (ATTR-285): 14.9 AMP

- Vertical installation (ATTR-286): yes

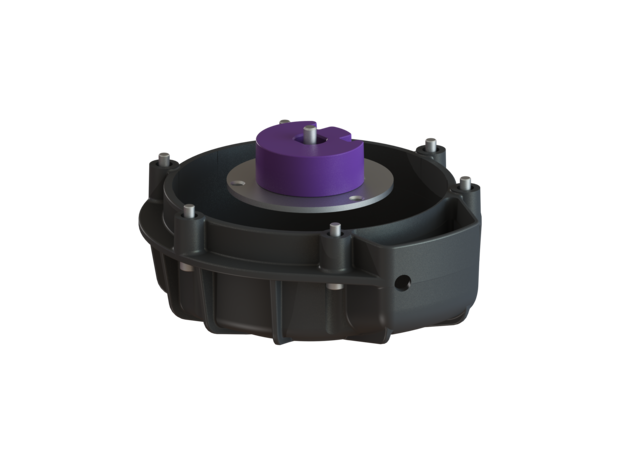

- Pump (ATTR-4): SPZ 1000

- Number of pumps (ATTR-181): 1

- Impeller type (ATTR-8): Macerator

- Type of pump connection cable (ATTR-N2): H07RN-F 3G 1.0 mm2

- Type of fuse required (electrical protection) (ATTR-N3): C 16 A

- Max. permissible switching frequency (ATTR-162): 20 1PH

- Operating mode (ATTR-10): S3 - 50 %

- Power P1 (ATTR-F4): 1.2 KWT

- Power P2 (ATTR-F5): 0.7 KWT

- Speed (ATTR-F2): 2,800 UMIN

- Rated current (ATTR-N5): 5.2 AMP

- Max. pumping capacity (ATTR-F7): 11.5 MQH

- Max. pumping height (ATTR-F8): 10 MTR

- Max. temperature (permanent) of conveyed material (ATTR-132): 40 CEL

- Protection class (ATTR-133): I

- Connection type (ATTR-N1): coded plug

- Protection class (pump) (ATTR-125): IP 68 (3m/48h)

- Length of mains cable for pump (ATTR-11): 5 MTR

- Temperature monitoring (ATTR-135): integrated

- Weight (ATTR-191): 10 KGM

- Cos phi - power factor (ATTR-192): 1.0

- Insulation class (ATTR-193): F

- Expected service life (hours of operation) (ATTR-194): 5,000 HUR

- Expected service life (number of switching cycles) (ATTR-195): 150,000

- Nominal size (DN) (ATTR-118):

200

- Note on nominal size (ATTR-118B): Hydraulics correspond to DN 150

- Outer diameter (OD) (ATTR-147): 200

- Net weight (ATTR-A3A): 28 KGM

- Gross weight (ATTR-A3B): 33.5 KGM

- Installation depth (ATTR-B2_VB): 486 MMT

- Vertical adjustment (ATTR-177): vertically adjustable upper section

- Length (ATTR-A6A): 720 MMT

- Width (ATTR-A6B): 590 MMT

- Cutout dimension, length (ATTR-160): 750 MMT

- Cutout dimension, width (ATTR-161): 750 MMT

- Volume (ATTR-320): 0.3 MTQ

- Packaging dimension: length (ATTR-325): 785 MMT

- Packaging dimension: width (ATTR-326): 615 MMT

- Packaging dimension: height (ATTR-327): 550 MMT

- Dimensions (ATTR-323): 785X615X550MM

- Number of packages (ATTR-321): 1

- Odour trap (ATTR-115): Multistop

- Emergency closure (ATTR-153): yes

- Pump control (ATTR-134): Control unit

- Socket version (ATTR-233): including spigot and socket

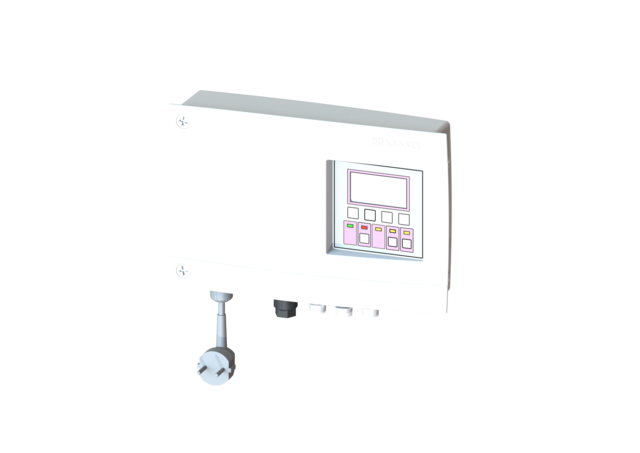

- Control unit (ATTR-S2):

Comfort

- Self-diagnosis system (SDS) (ATTR-S5): yes

- Battery buffering (ATTR-S6): yes

- Multi-line display (ATTR-S7): yes

- Log book function (ATTR-S8): yes

- USB interface (ATTR-S9): no

- GSM interface (ATTR-S10): no

- Potential-free contact (ATTR-S11): yes

- Length of mains cable for control unit (ATTR-S12): 1.4 MTR

- Operating voltage (ATTR-S13): 230 VLT

- Mains frequency (ATTR-S14): 50 HTZ

- Protection class control unit (ATTR-S4): IP 54

- Alarm sensor (ATTR-S1): optical probe

- Type of level measurement (ATTR-7A): optical

- Level measurement instrument (ATTR-7B): optical probe

- Pressure pipe connection (OD) (ATTR-B18): 40 MMT

- Nominal pressure (PN) (ATTR-B18B): 6

- Type of cover (ATTR-A21): tileable cover plate

- Load class (ATTR-A2B): K 3 (EN 1253-1)

- Locking (ATTR-A2D): Lock & Lift

- Cover material (ATTR-A2E):

Polymer

- Drainage function (ATTR-A2H): yes

- Max. flooring height (ATTR-A2L): 16 MMT

- Length (ATTR-A2M): 366 MMT

- Width (ATTR-A2N): 366 MMT

- Passage seal for conduit pipe (DN) (ATTR-184): 50 MMT

- Declaration of Performance (DOP) (ATTR-292): 009-036

- Wastewater quantity (ATTR-310):

Medium

- Protection strategy (ATTR-311):

Central protection

- Type of wastewater (ATTR-6):

wastewater with sewage

- Position relative to sewer (ATTR-309):

Gradient to the sewer

- Function in the event of backwater (ATTR-312):

Drains in the event of backwater

- Protection class probe (ATTR-175): IP 68 (3m/48h)

- Colour (ATTR-102): black

- Protection class motor (ATTR-174): IP 68 (3m/48h)

- Motor type (ATTR-120B): KSM 140

- Approval (ATTR-A5): Z-53.2-487

- CE marking (ATTR-A5B): no

- Number of motor-driven backwater flaps (ATTR-3A): 1

- External monitoring (ATTR-A8): LGA

- Vertical drop between inlet and outlet (ATTR-176): 9 MMT

- Delivery state (ATTR-189): Pre-mounted for final assembly on site (pumps and sensor system must be fitted on site and control unit must be connected)

- Declaration of conformity (ATTR-289):

yes

- Brand (M-ATTR-001): KESSEL

- Product group (M-ATTR-002): Hybrid lifting stations

- Product type (M-ATTR-003): Backwater lifting station

- Product family (M-ATTR-004): Ecolift

- Product name (M-ATTR-005): Ecolift

- Standby power (ATTR-S20): 5 WTT