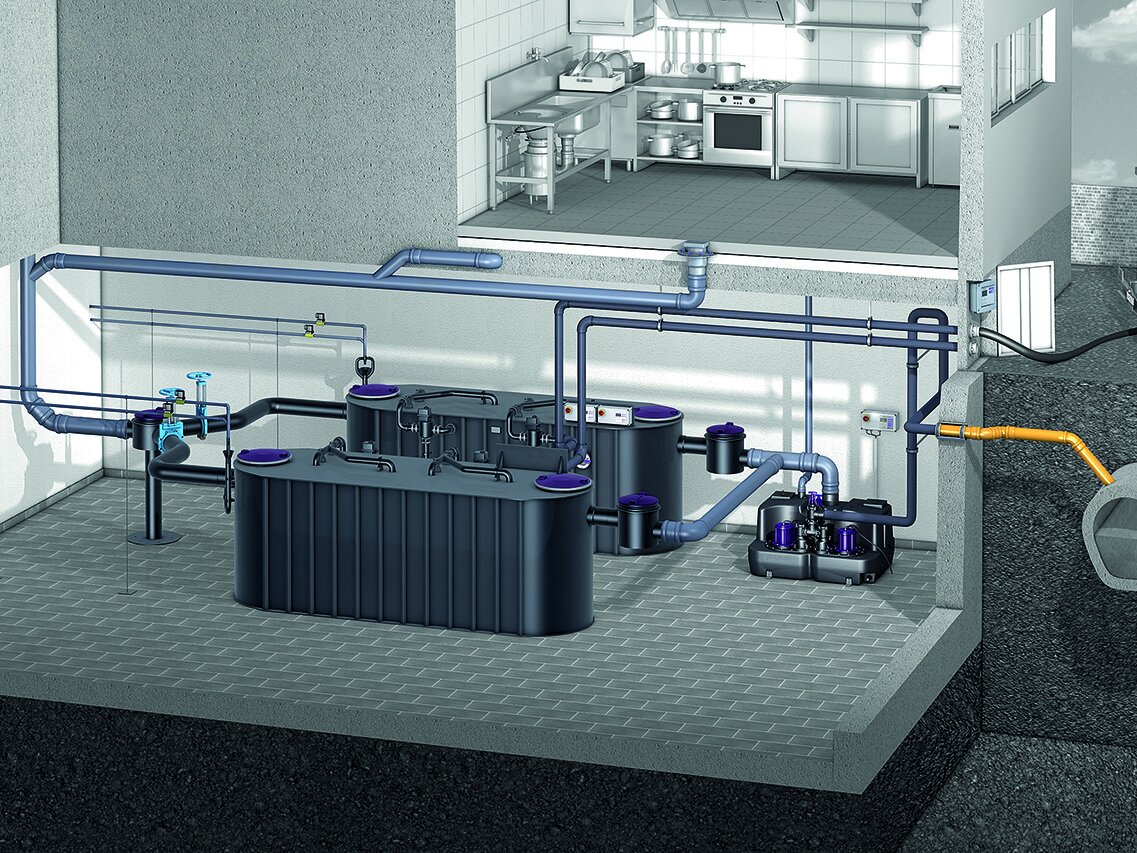

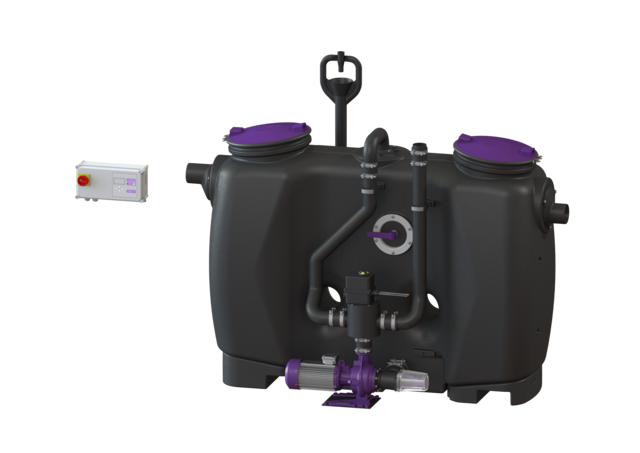

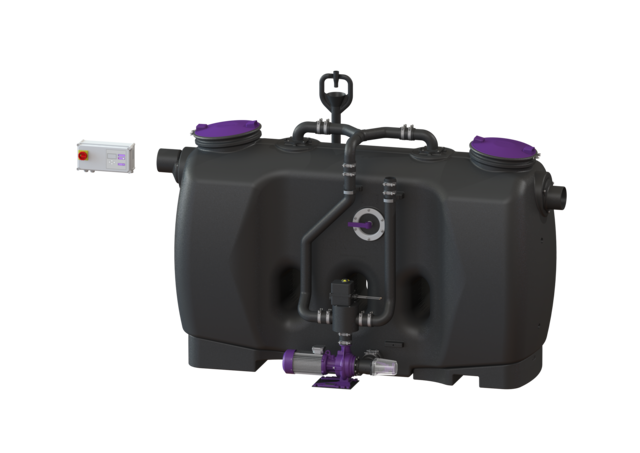

As good as it gets. The EasyClean free Auto Mix & Pump grease separator simply has everything: program-controlled, fully-automatic disposal and rinsing equipment, shredder-mix system, disposal pump,, direct disposal pipe and control unit. The contents of the closed tank are disposed of through permanently installed pipes into the disposal vehicle. The system’s own pimp is used if the disposal pipe is so long that the disposal vehicle’s pump is not sufficient. The shredder-mix system is used to circulate and homogenise the contents of the tank for easy disposal.

The grease separator is available in nominal sizes NS 2 to NS 10, which is sufficient for most businesses such as restaurants and hotels. It is also available in nominal sizes NS 15 to NS 50 for larger volumes of wastewater. In addition, we also offer individual solutions for specific requirements and installation situations.

The EasyClean free Auto Mix & Pump combines all advantages in one unit:

- Direct disposal: Disposal via the direct disposal pipe – without opening the tank.

- No odour emissions: The shredder-mix system ensures odourless disposal and cleaning.

- Central control: The shredder-mix system and refill inlet can be controlled via the control unit.

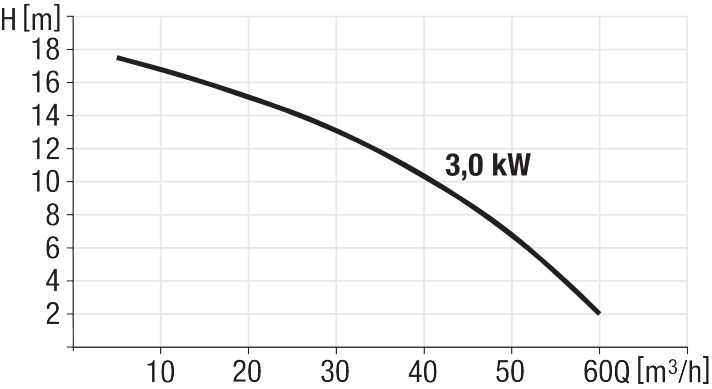

- Disposal pump: For installation situations in which the disposal vehicle can no longer extract the wastewater.

- Fully automatic: The disposal and rinsing take place fully automatically and program-controlled.

100 % corrosion-free – 20-year guarantee

Our grease separators are made of polyethylene. That makes them resistant to aggressive fatty acids and they are therefore particularly durable. Trust in KESSEL quality: In addition to the statutory provision, we provide a 20-year warranty with regard to the leak tightness, fitness for purpose and structural stability of tanks and upper sections.

SonicControl

The SonicControl automatic layer thickness measuring device with ultrasound sensor precisely monitors the temperature and thickness of the grease layer in grease separators. Owners/operating companies can verify the actual quantity of grease produced to the relevant authorities and optimise the necessary disposal cycles outside of standard requirements.

EasyClean free Auto Mix & Pump

SonicControl: no | |||||

Inspection window: yes | |||||

| Inlet nominal size (DN) | Nominal size (NS) | Refill inlet in accordance with DIN 1988 | Item no. | ||

|---|---|---|---|---|---|

93002.01/PVS | 100 MMT | 2 | yes | 93002.01/PVS | Show |

93003.01/PVS | 100 MMT | 3 | yes | 93003.01/PVS | Show |

93004.01/PVS | 100 MMT | 4 | yes | 93004.01/PVS | Show |

93007.01/PVS | 150 MMT | 7 | yes | 93007.01/PVS | Show |

93010.01/PVS | 150 MMT | 10 | yes | 93010.01/PVS | Show |

93015.01/PVS | 200 MMT | 15 | yes | 93015.01/PVS | Show |

93020.01/PVS | 200 MMT | 20 | yes | 93020.01/PVS | Show |

93025.01/PVS | 200 MMT | 25 | yes | 93025.01/PVS | Show |

93030.01/PVS | 250 MMT | 30 | yes | 93030.01/PVS | Show |

93035.01/PVS | 250 MMT | 35 | yes | 93035.01/PVS | Show |

93040.01/PVS | 250 MMT | 40 | yes | 93040.01/PVS | Show |

93050.01/PVS | 250 MMT | 50 | yes | 93050.01/PVS | Show |